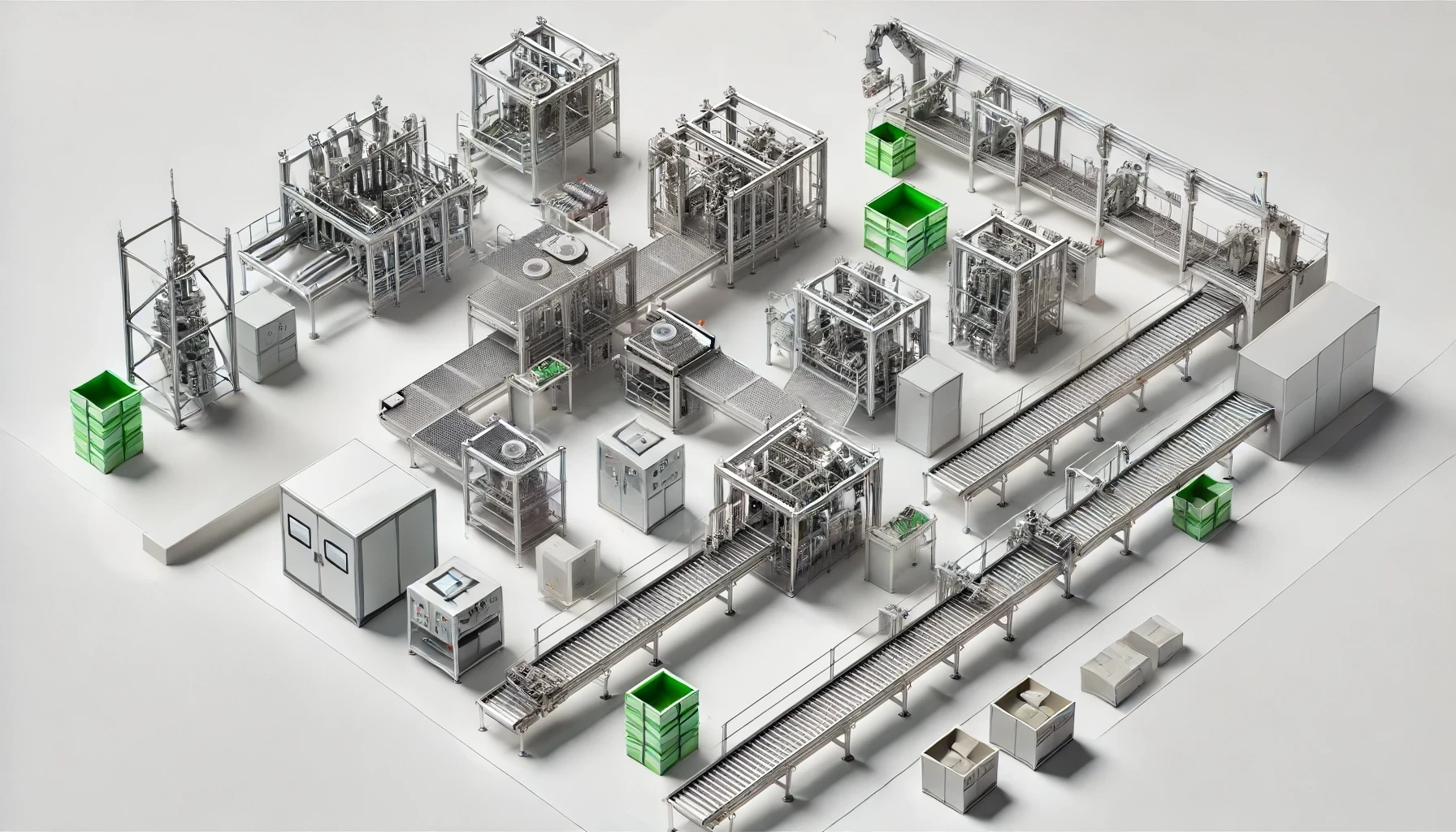

TEAM Automation Berlin solutions are applied in many industries and can be flexibly adapted to the specific requirements of different sectors. Whether it is the automotive industry, electrical engineering, medical technology, or packaging technology – TEAM Automation Berlin offers tailored automation solutions that increase efficiency, precision, and quality in your production. Learn more about our industry expertise and find the best solution for your needs.