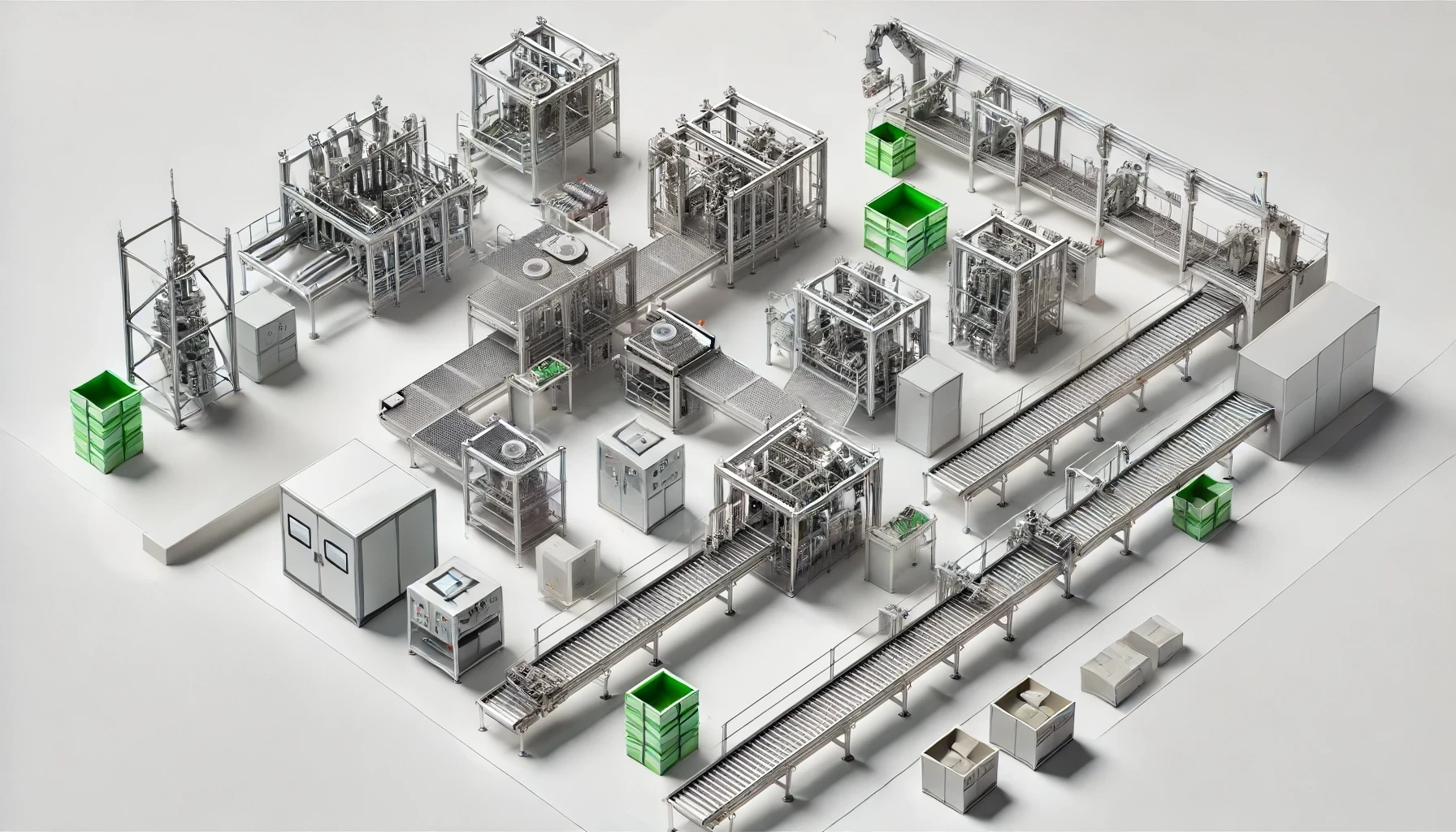

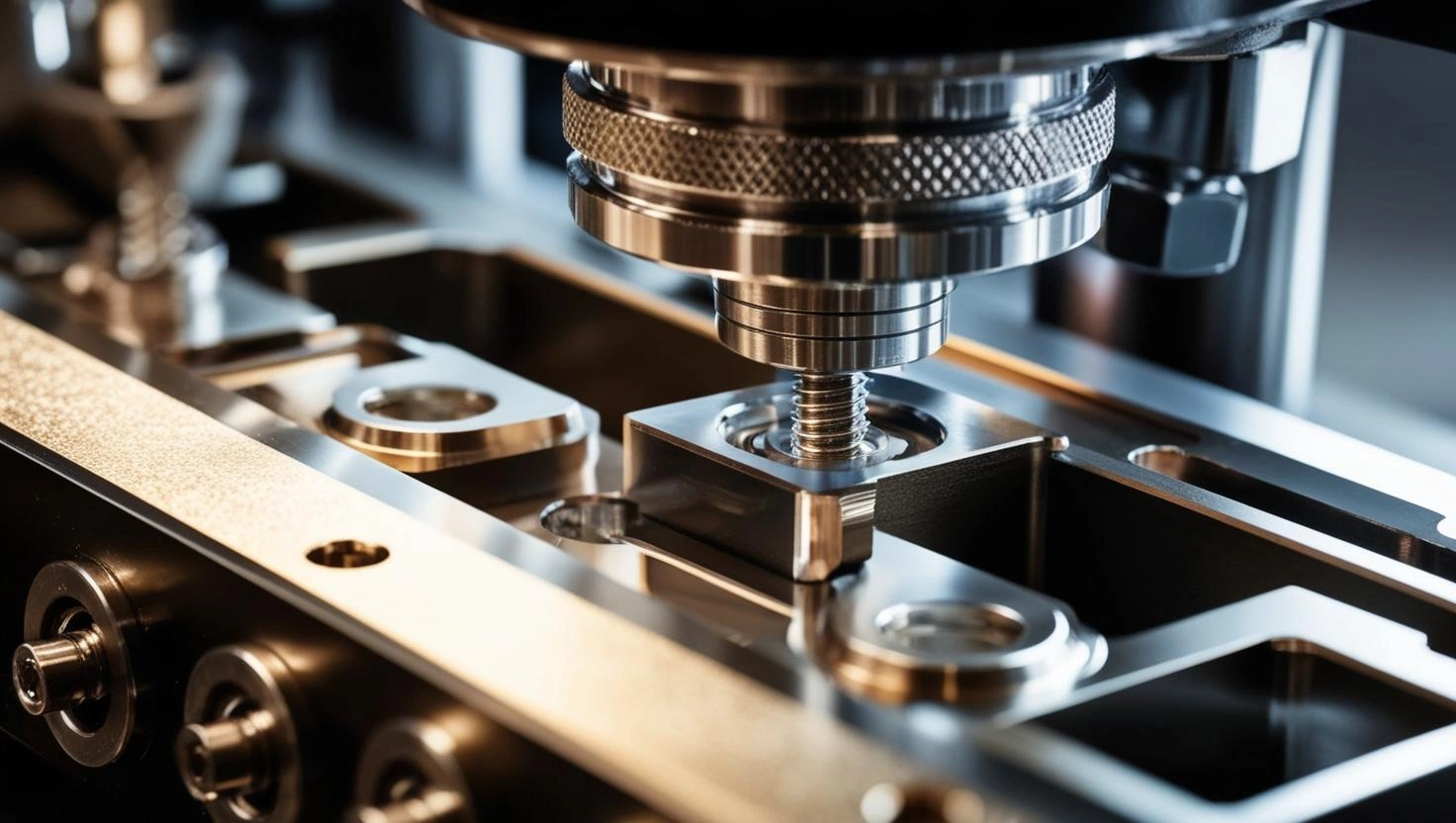

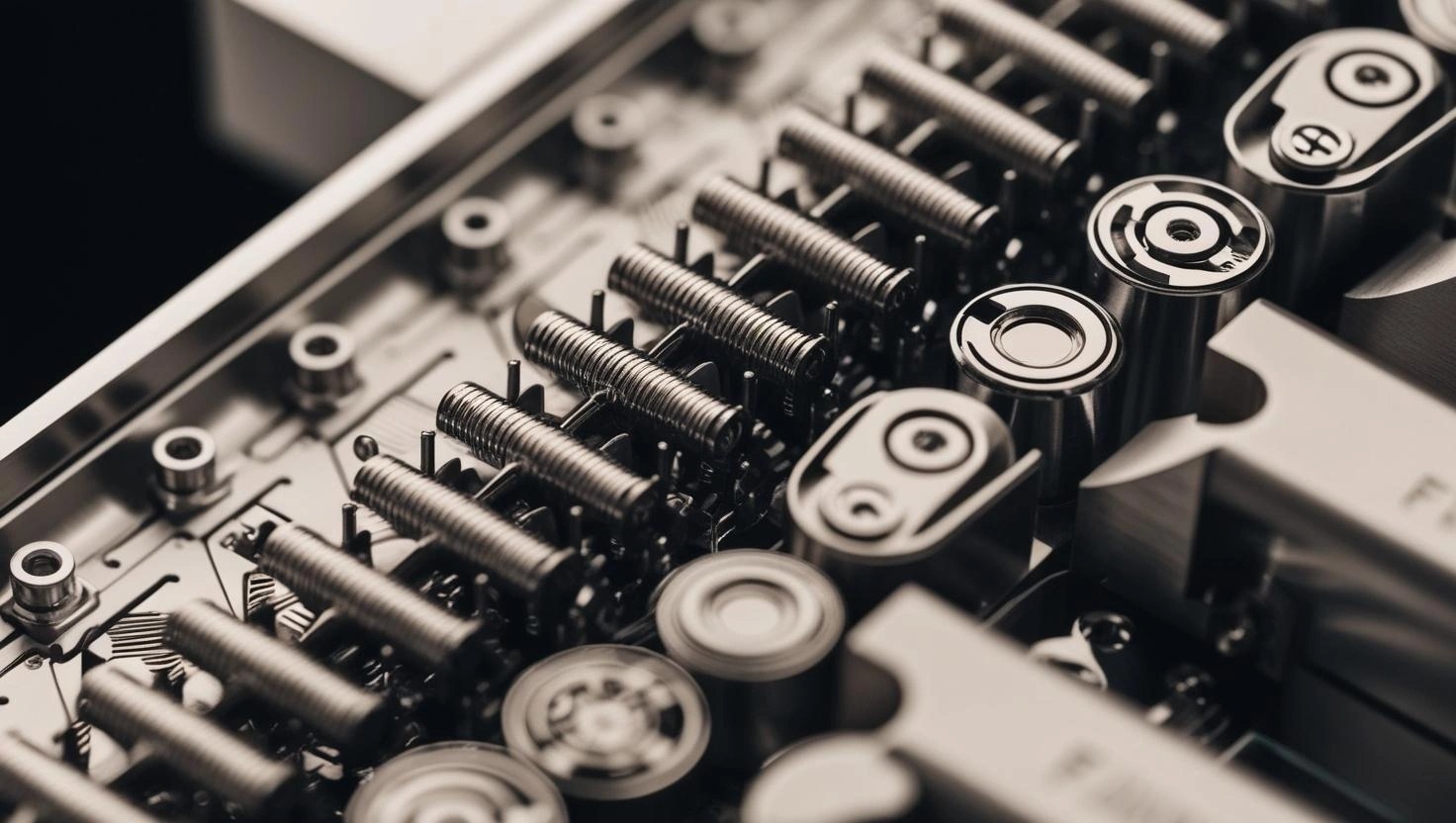

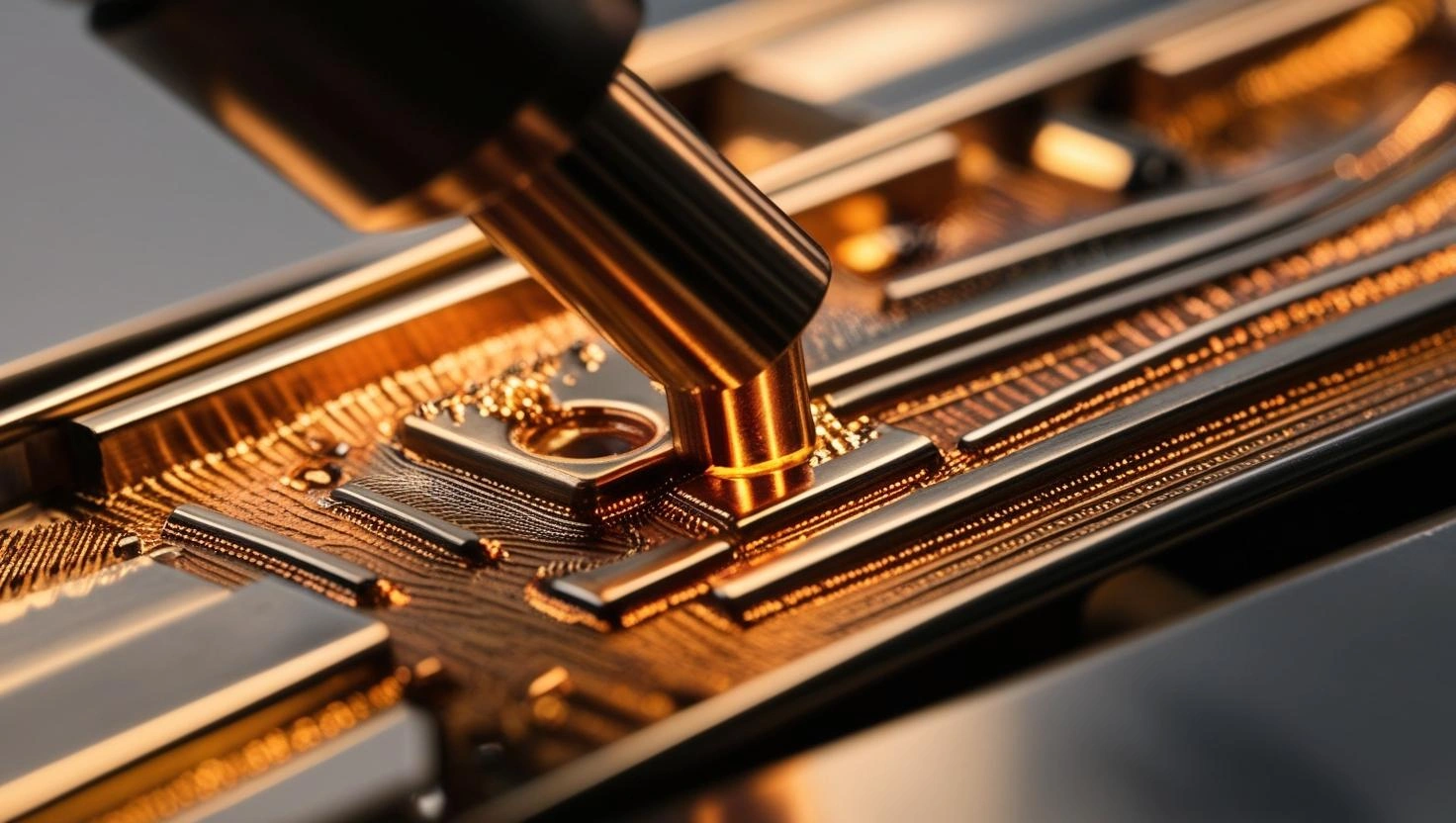

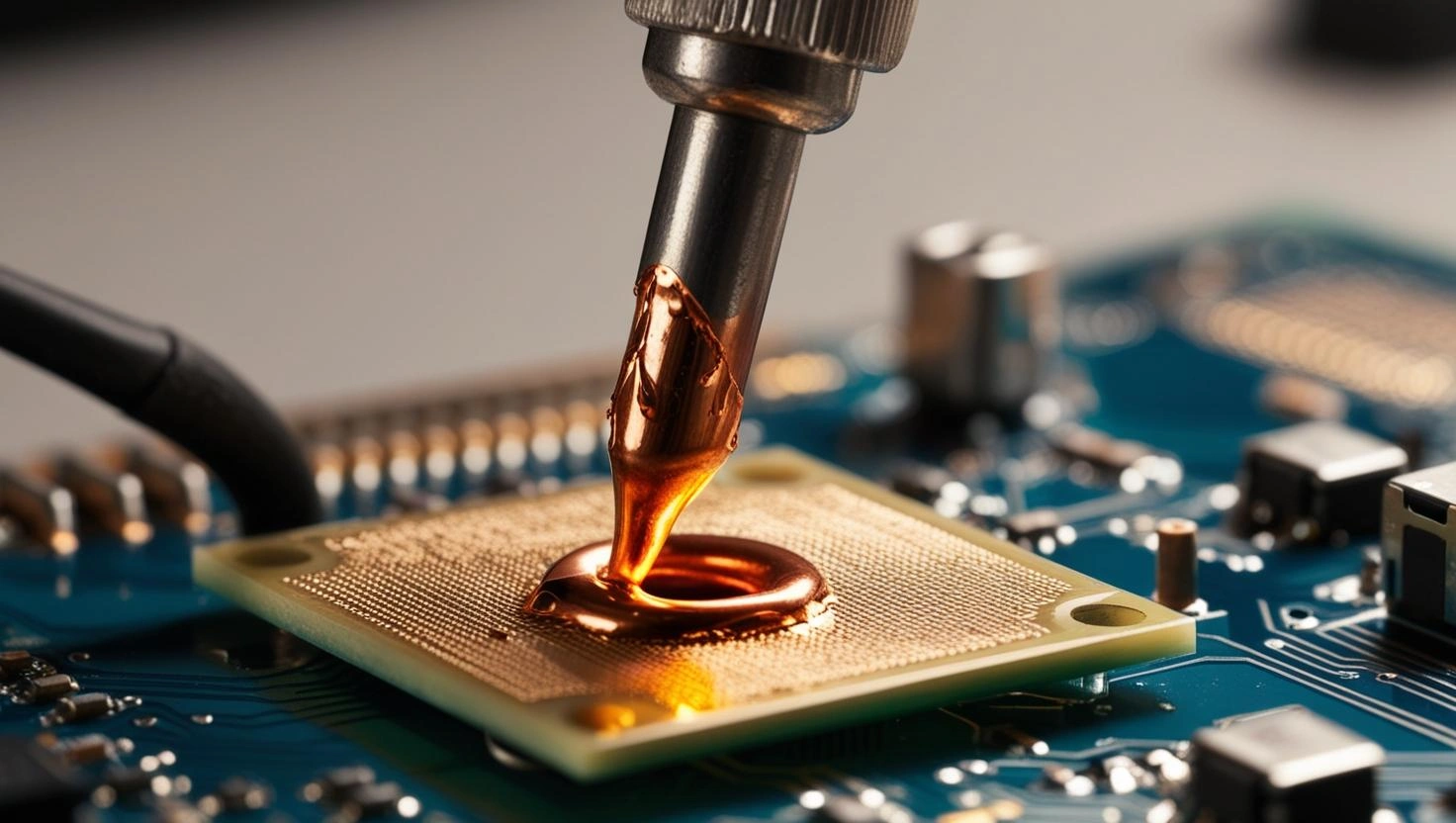

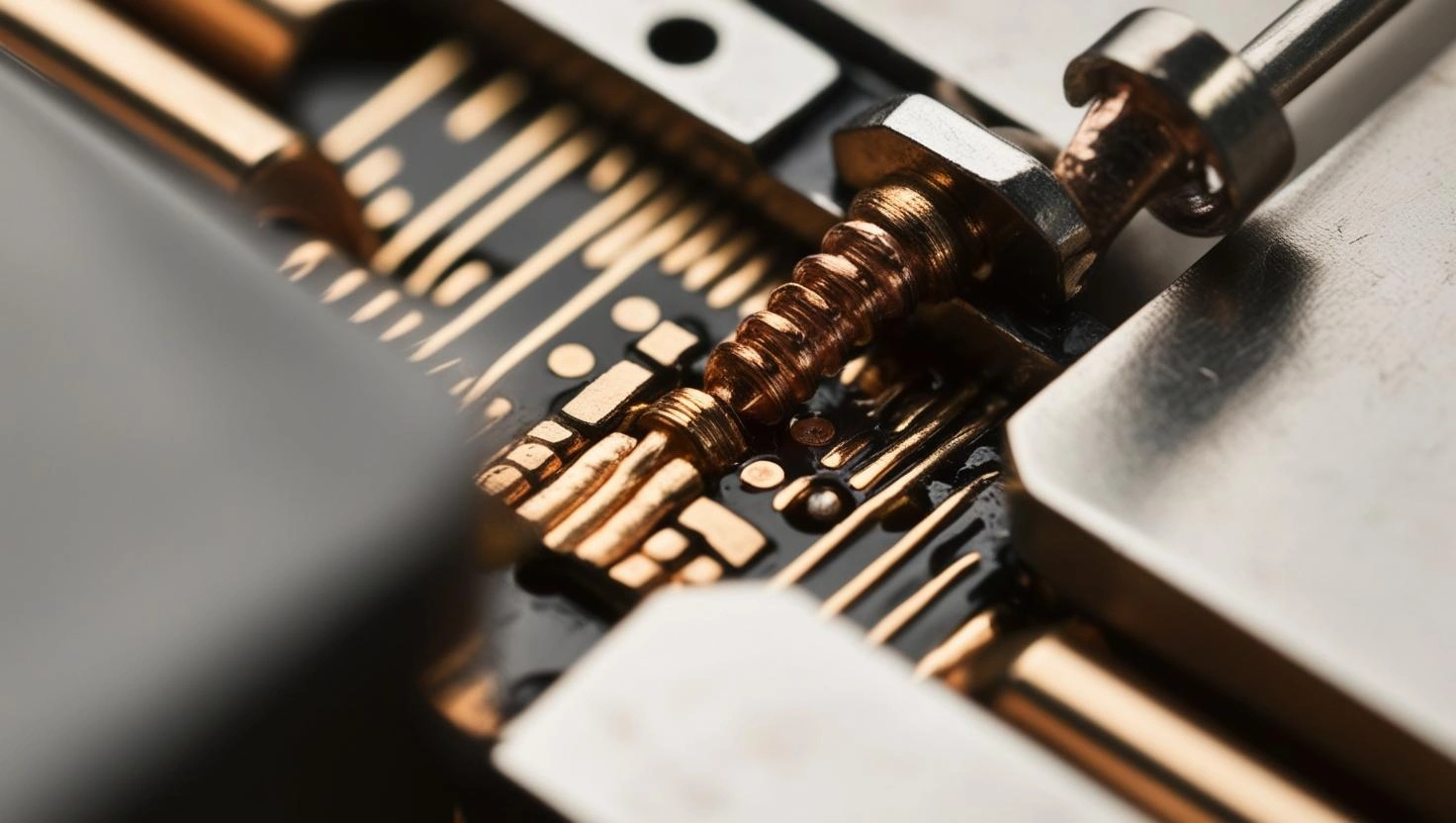

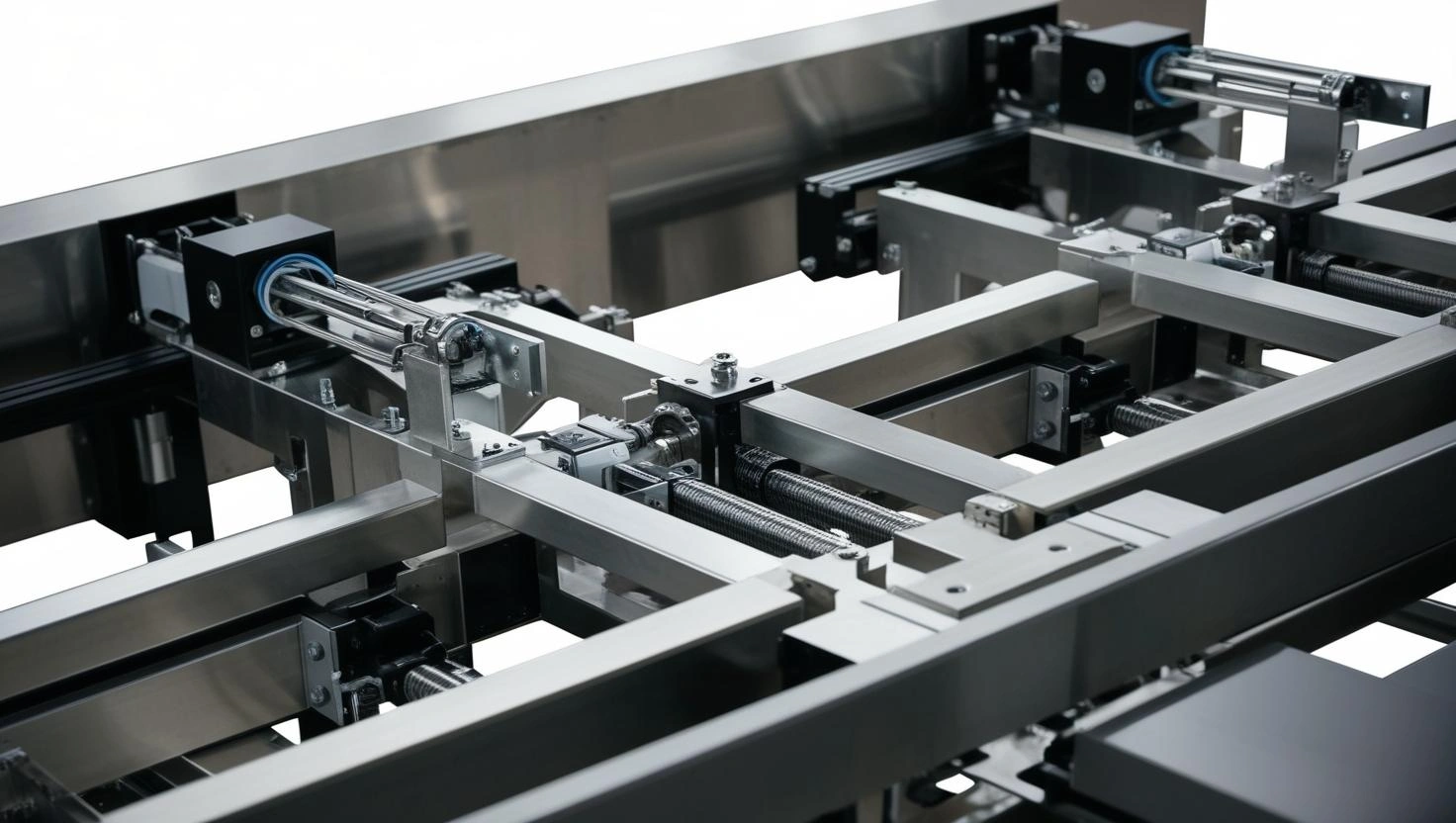

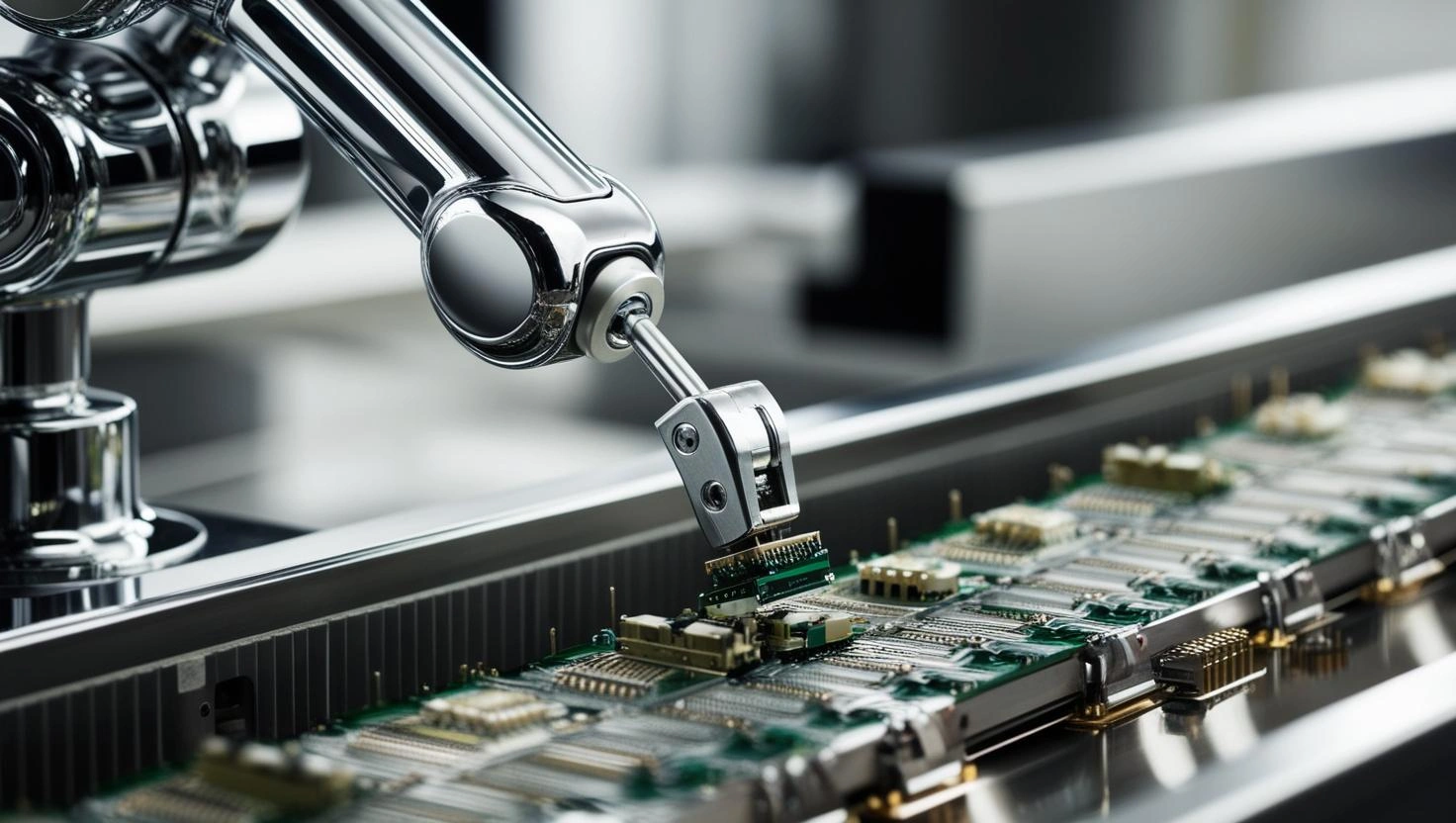

Efficient and well-thought-out processes are the key to high productivity and quality. TEAM Automation Berlin optimizes and automates production and assembly processes to reduce cycle times, minimize errors, and make the best use of resources. Discover how tailored solutions can streamline your production processes and prepare them for the future.