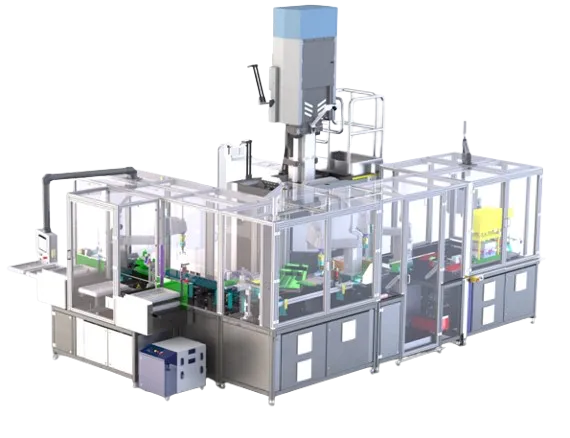

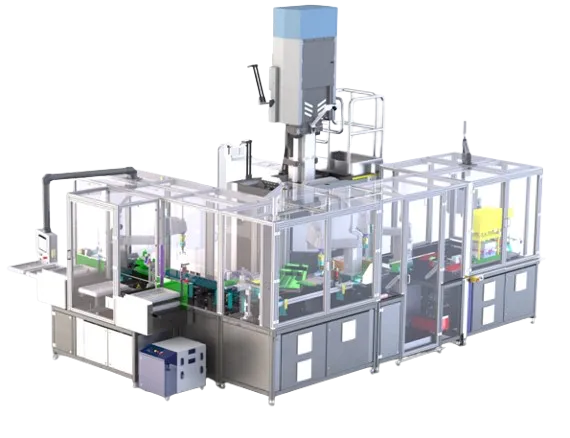

Fully automatic assembly systems interconnected either by a flexible workpiece-carrier circulation system or by robots that work in unison.

Fully automatic assembly systems interconnected either by a flexible workpiece-carrier circulation system or by robots that work in unison.